Why are Cocopeat, Cocofibre and Coco Chips good substrate raw materials?

Cocopeat (coconut pulp), Cocofibre (coconut fibres) and Cocu Chips are sufficiently available in the countries of origin such as India and Sri Lanka as residual materials from coconut processing and have meanwhile also proven themselves excellently as peat substitutes in professional horticulture.

Our Coco products are basically much better than their reputation in terms of environmental compatibility. Despite the long transport routes, Cocopeat and Cocofibre have a relatively good CO2 balance. They are renewable and are transported very compactly by ship to the destination ports near the production sites.

Another advantage in terms of the CO2 balance is that they are residual materials whose recycling is in line with the circular economy. In addition, the coco products purchased by Gramoflor are manufactured in accordance with the SA 8000 social standards.

Our Coco Chips are made from shredded coconut husks and offer an excellent, coarse-grained structure for substrates. As a peat-free alternative to coarse white peat, Coco Chips are characterised by their very good structural stability, which is demonstrably even superior to that of white peat.

The natural fibre content promotes the air capacity of the substrate, which is essential for healthy root development, among other things. Coco Chips, especially in combination with our wood fi bre variants LIGNOFIBRE®c coarse and LIGNOFIBRE®, are the perfect addition to your substrate from pot size 13.

Thanks to the water retention in the coarse pieces, Coco Chips support sustained moisture despite their coarse

structure

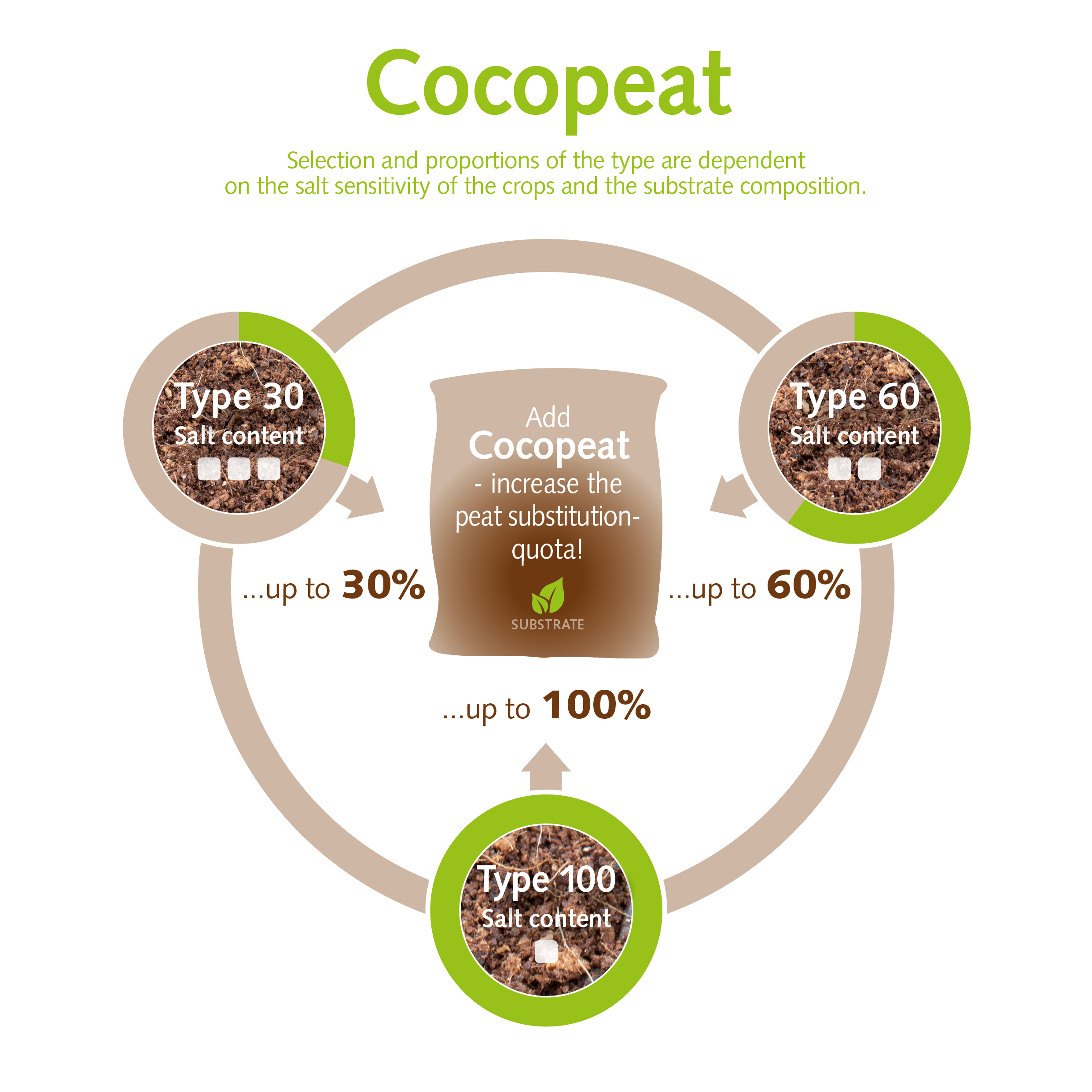

We process the raw material Cocopeat ourselves at our production plant using a specially developed process. A large proportion of the socalled leaching of unwanted salts/nutrients takes place under controlled conditions. Gramofl or is therefore able to process the Cocopeat and differentiate it into three types so that it can be tailored even more precisely to the respective cultivation requirements in terms of salt content and chemical properties.

This enables continuity in the chemical properties and thus an effective and safe use of coco products in the substrate.

Three Cocopeat quality levels are thus offered:

Type 30

Type 60

Type 100

- Type 30 for proportions in substrates up to 30%,

- Type 60 for proportions in substrates up to 60% and

- Type 100 for proportions in substrates of up to 100% and for particularly sensitive crops. Chemical buffering is no longer necessary.

All Cocopeat varieties are RAL quality assured and also FiBL listed for use in organic horticulture.